User Friendly / Operator Run

Create Full-line Solutions

Great Customer Support

-

Who We Are

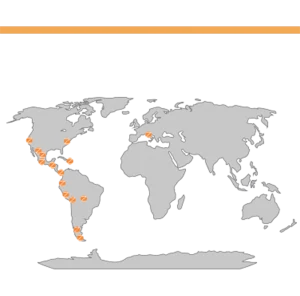

ZimaPack, LLC was started to fill a demand for true net weight filling at an affordable price. The company is headquartered in Chester, Virginia, and has representation throughout the United States, Latin America, and Europe. Our machines are designed and manufactured in the United States.

ZimaPack works with several representatives and agencies throughout the world to better serve its customers and provide the most effective packaging solutions.Our goal is to make quality machinery at a fair price while providing customers with simple and valuable packaging solutions.

-

What We Offer

Fillers: ZimaPack designs and manufactures Automatic Rotary Net Weight Fillers.

Monoblocks: We design Monoblocks with ZimaPack Fillers and can incorporate Rinsers, Cappers, and Sealers, depending on your needs.

Packaging Line Solutions: We provide solutions for complete lines. Our team can help integrate other packaging machinery and conveyor systems. We can also customize layouts according to your plant’s space and develop strategies based on your production line’s needs such as sterilization practices, adding chemical applications to your products, etc.

-

Why Choose Us?

ZimaPack Fillers are designed to be simple and efficient. These machines have the same technological advantages the more expensive net weight fillers on the market have but also add the advantages of a simplified machine that is easy to operate and maintain. This is due to its open structure and all commercial components. These non-proprietary parts allow your plant managers and engineers to handle routine service and maintenance. Onboard software allows many adjustments and repairs to be handled remotely.

Our Fillers are designed based on the requirements of your packaging line. They are custom-made for your product, container, and production speed.

ZimaPack Net Weight Fillers are cost-effective and provide exceptional consistency to your consumers. While volume changes with variables like temperature and barometric pressure, the net weight stays constant. That and the non-proprietary components make a ZimaPack machine a perfect solution for controlling your product giveaway and costs.

Other advantages of ZimaPack Net Weight Fillers are:

-Our nozzles fill without touching the bottles.

-We do not use friction gaskets, reducing the amount of water and time needed to clean the machine.

-During CIP (Clean in Place) internal and external cleaning there is no need to disassemble/take-off parts, unlike many volumetric fillers.

-The same machine can fill a wide range of bottle sizes and amounts of product.